Advanced Friction Additive Manufacturing

A new green AM era is coming soon, let’s go from CNC friction-based AM origin!

Welcome friends from academia and industry to join AFAMSology, the initiator of the emerging interdisciplinary discipline of friction additive technology! If you support AFAMS, AFAMS will be open to you!

- ATIIAM professional innovation company released the AFAMS technology research results for the first time, focusing on the original technology system of light alloy solid phase friction additive manufacturing for 10 years.

- AFAMS is the first CNC friction-based AM solution, which represents the latest development trend of the new generation of green additive manufacturing technology, with the technical characteristics of “high efficiency, high quality, low power consumption, low cost and environmental friendliness, value-added CNC technology chain and material standards”.

- ATIIAM is also the first high-tech professional company to carry out online training, technical consultation and solution provision in the field of innovation of friction solid phase additive manufacturing methods, and holds a series of original patents and application rights for friction solid phase additives.

Welcome to www.atiiam.com and please contact us with email at first time.

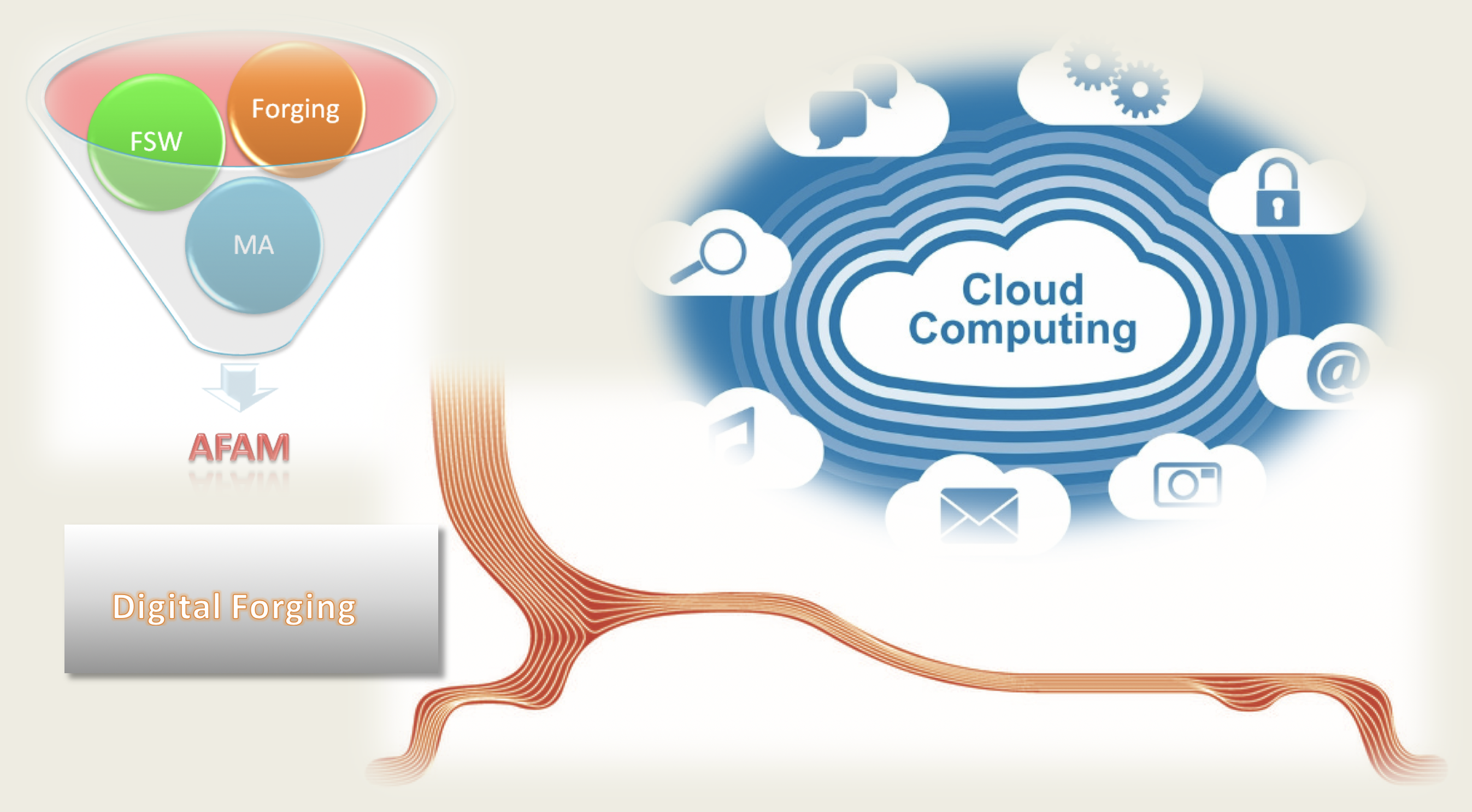

1. AFAMS is the abbreviation of Advanced Friction AM System:

- Advanced – concentrates the genes of many contemporary advanced processes,

- Friction – represents metal solid phase friction (solid phase is omitted here),

- AM – additive manufacturing,

- System – technology system.

- AFAMS is an innovative technology system proposed by ATIIAM for the emerging CNC friction-based AM industry. The system is mainly supported by three types of solutions:

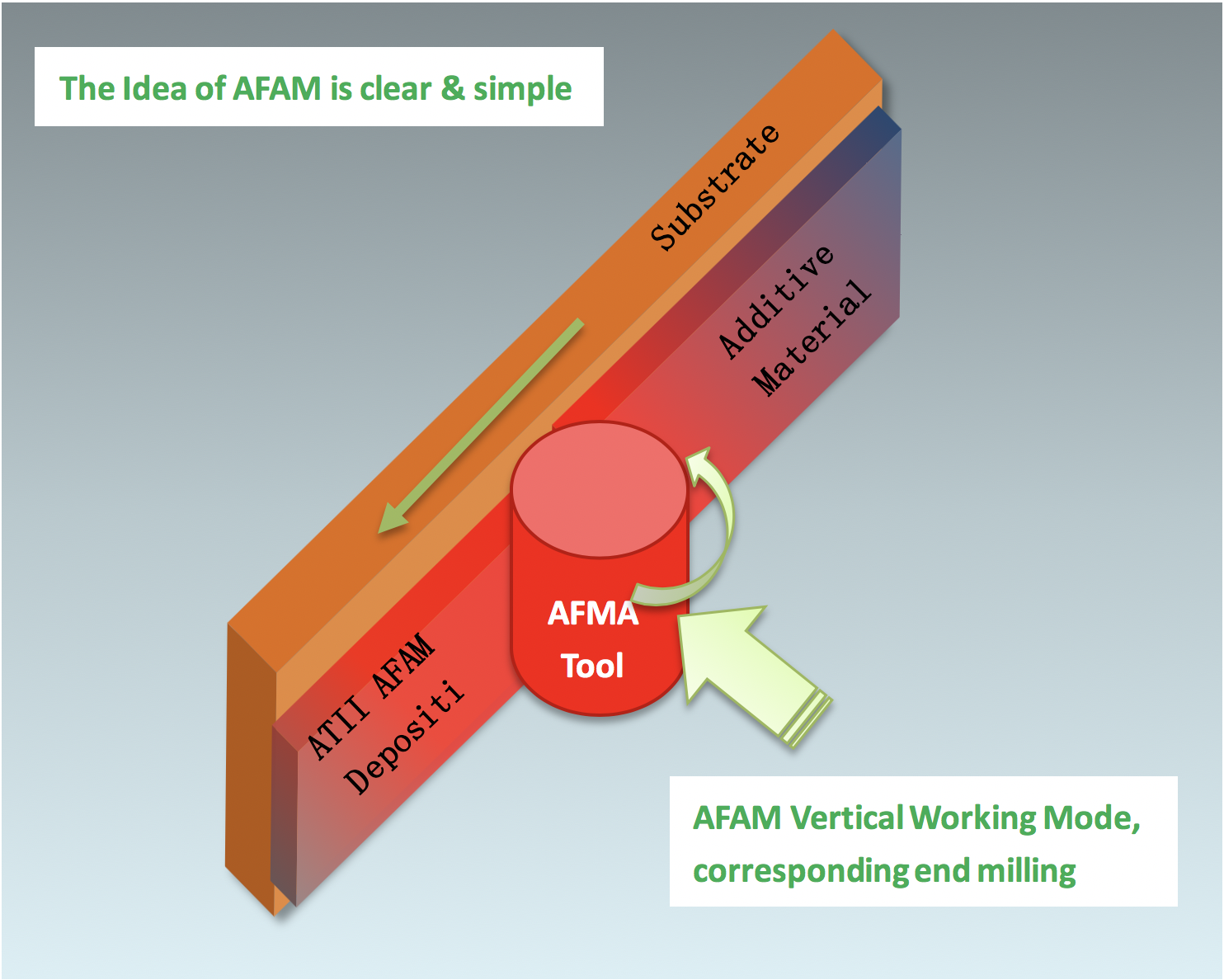

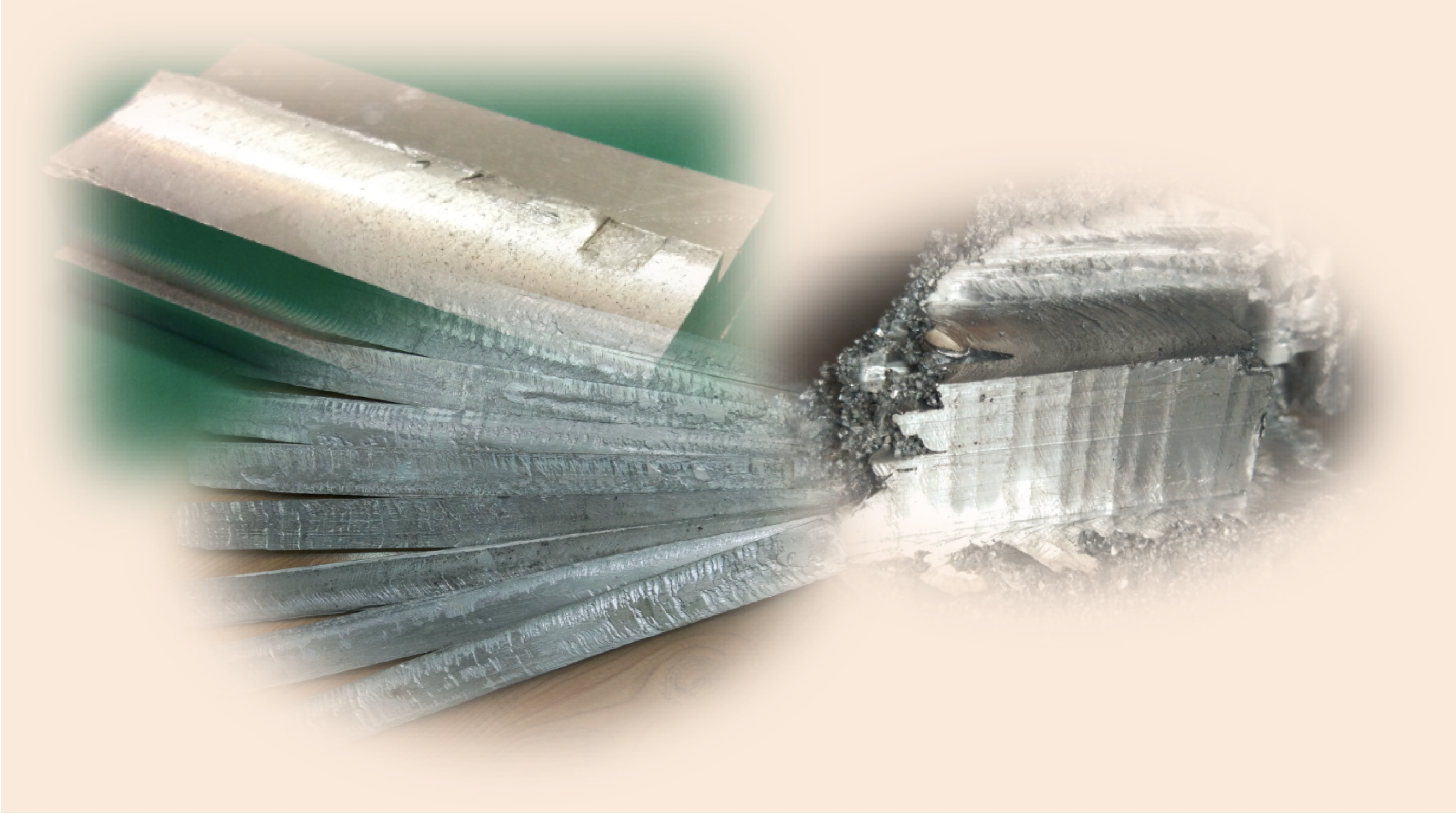

- AFAM – I (additive friction rolling deposition): The process is a solution proposed for the evolution of the microstructure of friction solid phase materials to reduce the initial R&D cost and the need for fine-grained rapid manufacturing using casting materials.

- AFAM – II (extracting + rolling deposition): A solution proposed for the extrusion process and the use of additive materials.

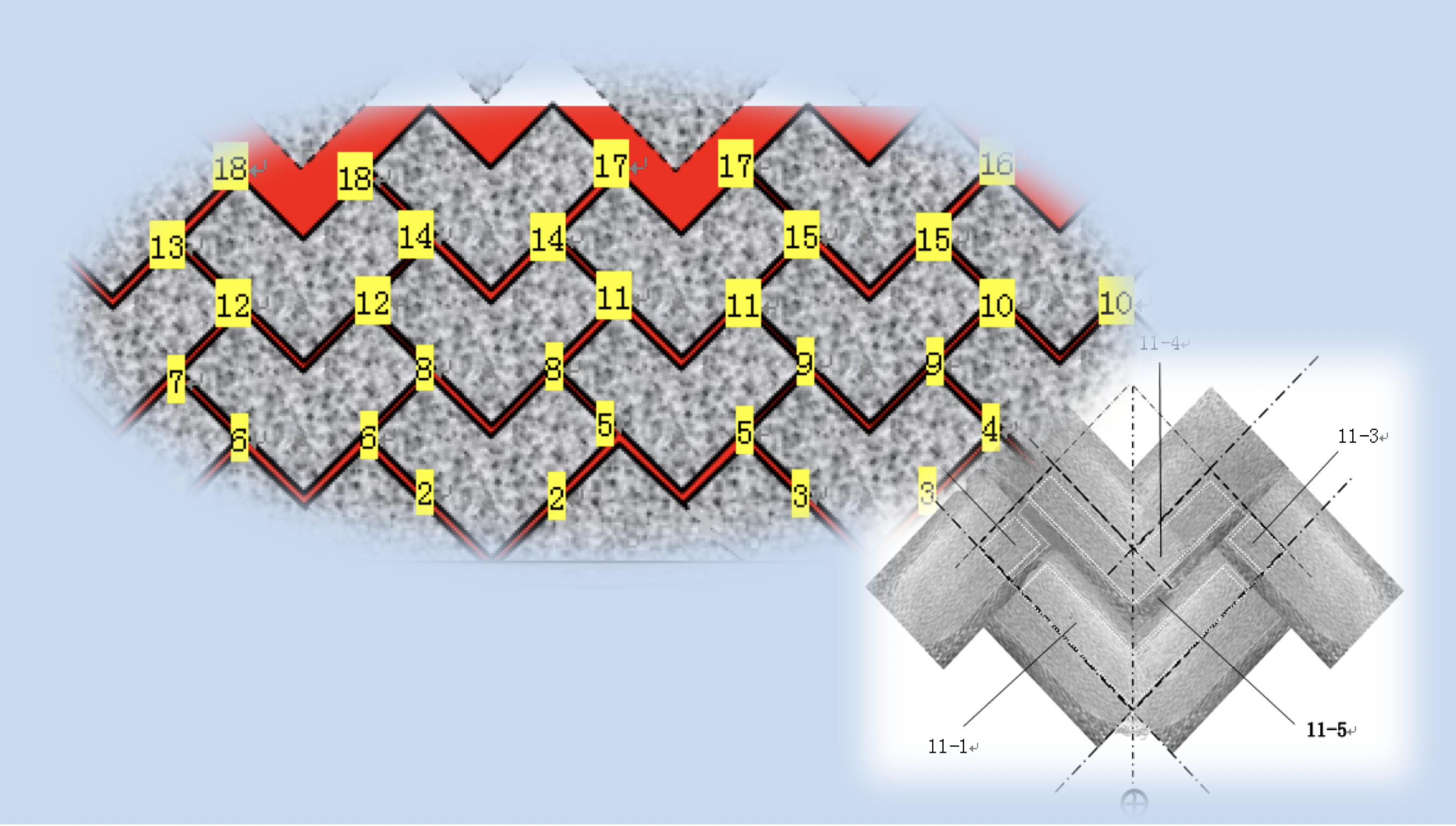

- AFAM – III (forging line + rolling deposition): A solution proposed for the forging process, the deformed materials used and high-quality important parts. Or it is called a forging line additive part. The CNC tool welding path is designed according to the streamline direction of the part. The innovation of this process in terms of materials is that the combination of coarse and fine grain gradient materials (incomplete grain processing) can be used to achieve part strength and toughness control, so that the additive rate will be greatly increased.

- The above text briefly summarizes the research results that ATIIAM has spent 10 years on. Their technical essence can provide rapid additive manufacturing technology upgrade solutions for the casting, extrusion and die forging industries. This is a grand goal and vision, and it is also a huge responsibility that a small technology company that specializes in research on process innovation cannot afford. Therefore, ATIIAM chose technical training, promotion and popularization to provide solutions for emerging industries, and is committed to spreading interdisciplinary innovation methods and knowledge, so that partners can benefit from it on the product and service side.

2. AFAMS Road Map:

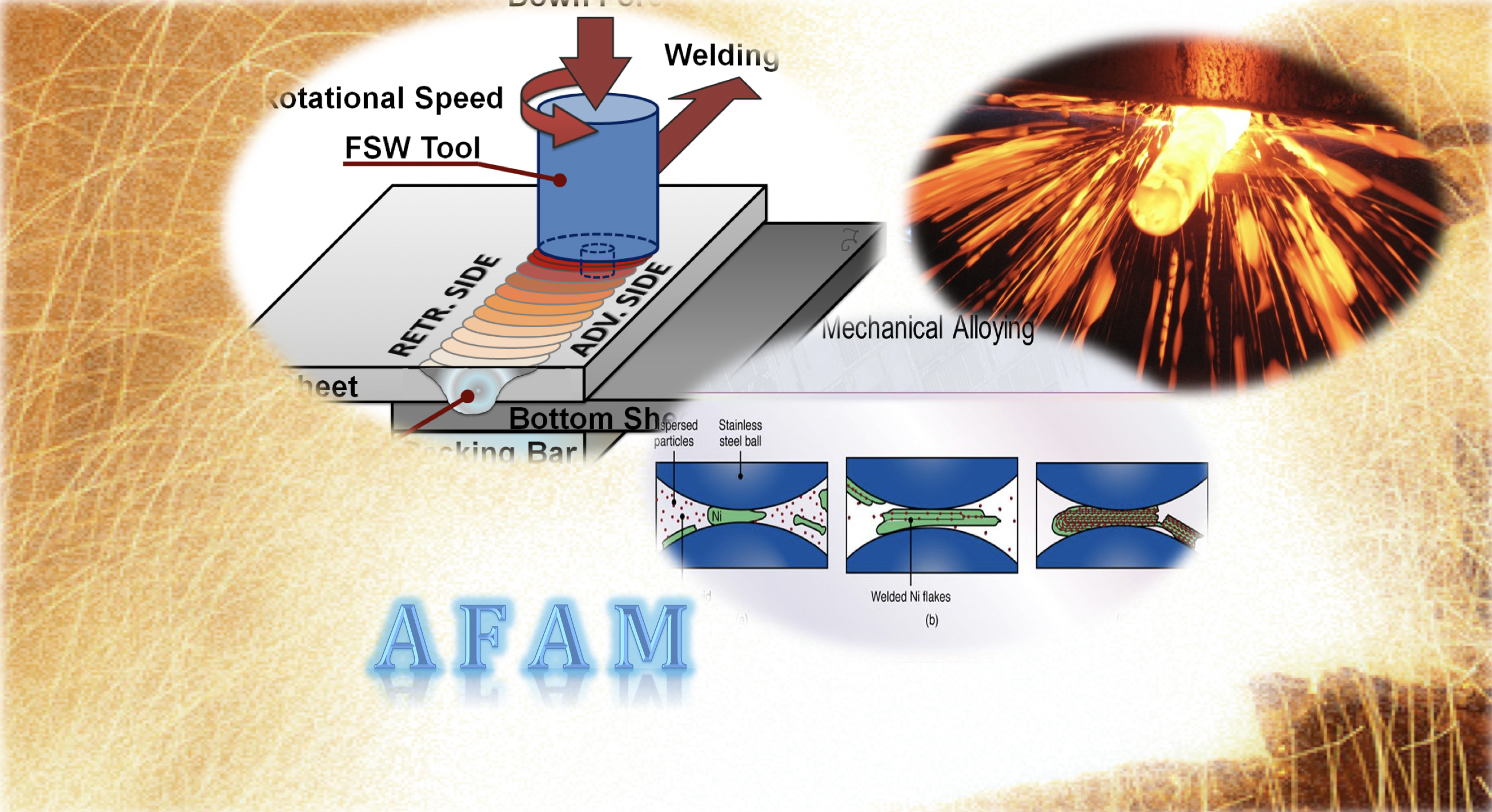

- From 2015 to 2016, the friction stir welding FSW and friction stir additive manufacturing FSAM were followed up, and the forward edge of the FSW tool was locked as the origin of stress concentration and abnormal grain growth. The algorithm rules of the pure core fine grain block of the tool head were designed, and the first patent application was filed.

- In 2017, it was discovered that the universal principle or necessary and sufficient conditions for the innovation of friction solid-phase additive methods are: mutual extrusion and friction between metal materials (newly added materials and substrates or previous layers of materials) – sufficient molecular and atomic friction vibrations – macroscopic relative motion between friction surfaces, verifying the lateral additive method of CNC tool heads, and applying for a patent for rolling friction deposition AFAM-I (additive friction rolling deposition) that can be used for additives, helping a large research institute’s FSW research center to prepare additive samples using the AFRD process.

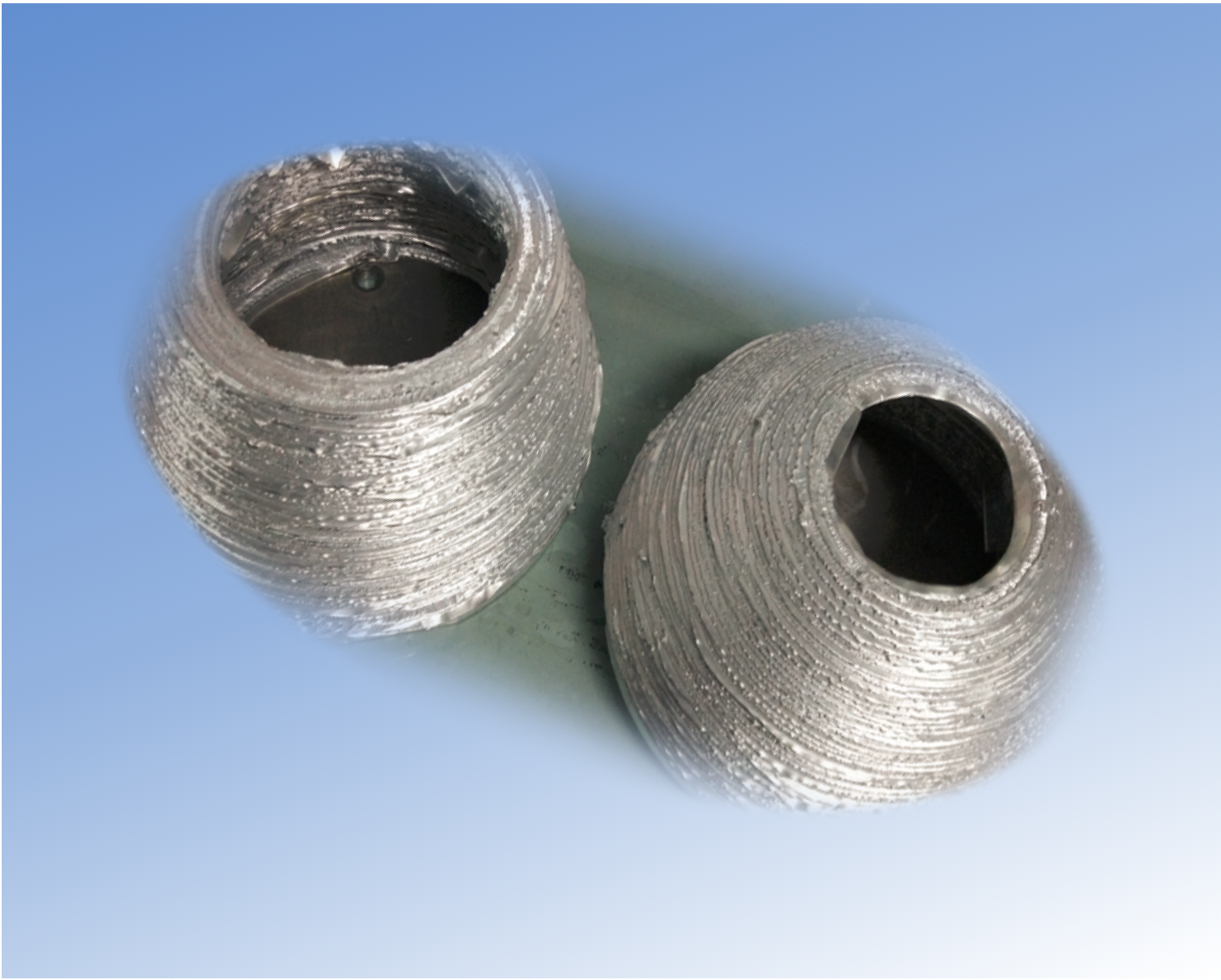

- In 2018, the lateral additive tool head was designed and prepared, and 5 ring parts were prepared using the AFAM-I process, and a Chinese cover article was published in the “World Nonferrous Metals” magazine.

- In 2019, the first version of the website was released, the research results of AFAM-I (AFRD) were made public, and the first university was helped to establish a friction solid-phase additive manufacturing research laboratory, which later formed its own technical branch.

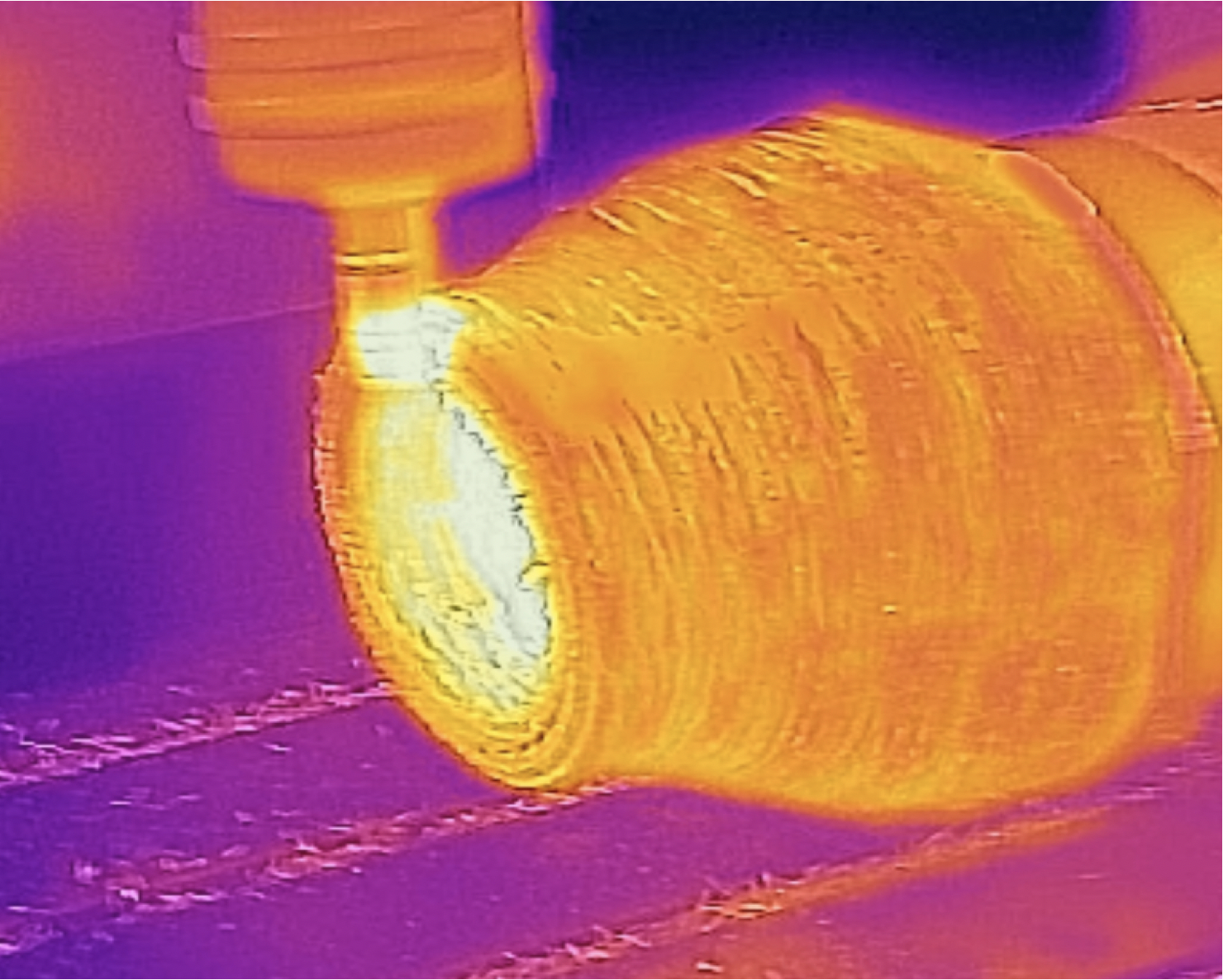

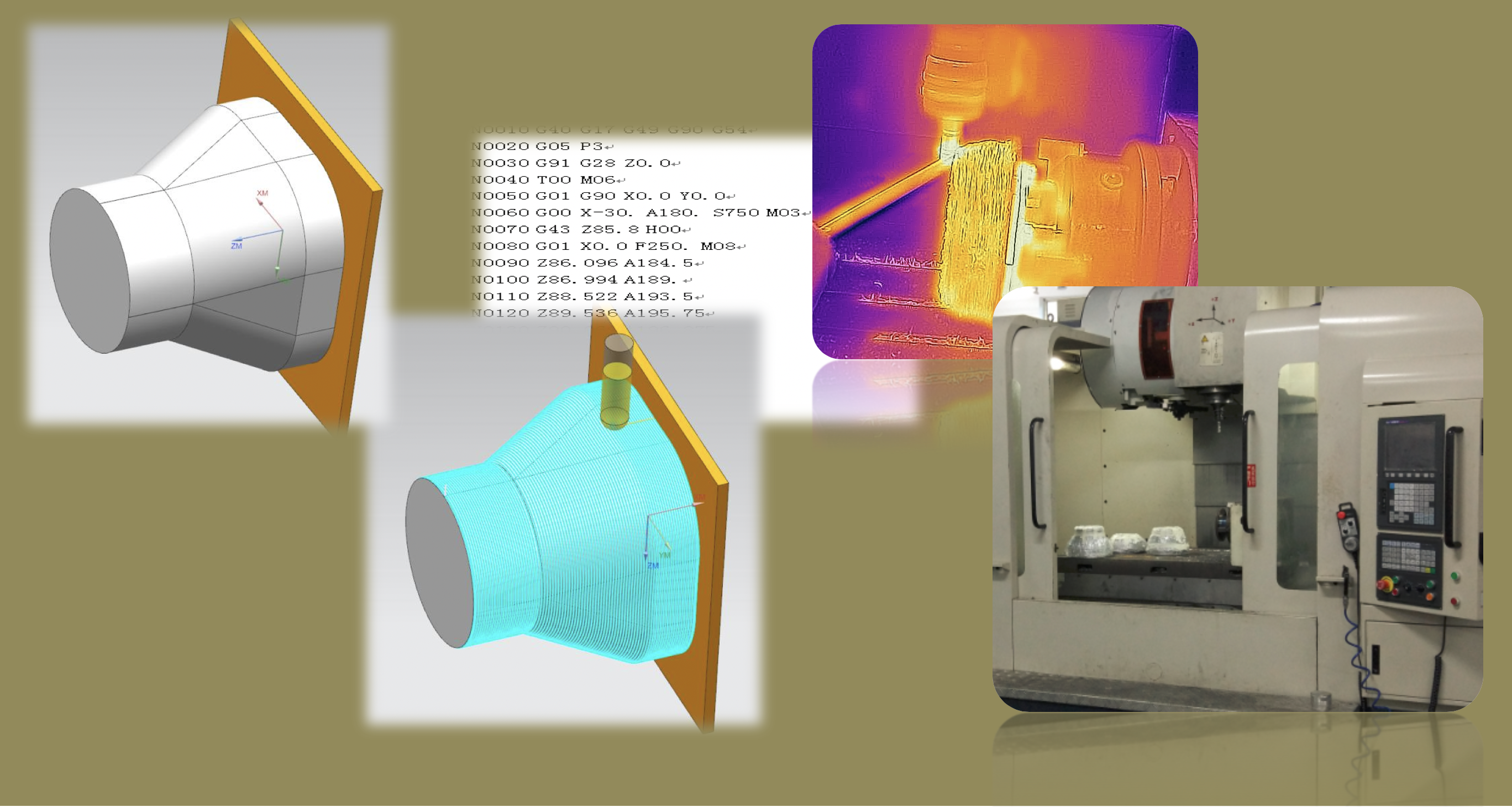

- In 2020, the first 5-axis horizontal machining center was transformed, and the forming technology of linear arc parts and complex ring parts was studied. The phenomenon of abnormal grain growth AGG in the additive organization was overcome, and the thermal stability of the AFAM-I additive organization was verified. The performance of the additive organization of 6 series materials was studied.

- In 2021, experimental research on the design of additive tool heads, printing of spherical parts, and performance research on the additive organization of 2 series aluminum alloy materials were carried out.

- In 2022, experimental research on the design of additive tool heads, gradient interface research, and the AFAM-II structural scheme was designed for the friction additive process required for extrusion performance parts, helping the first university to establish a friction solid phase additive manufacturing research laboratory, and the performance research of the additive organization of 7 series aluminum alloy materials.

- In 2023, experimental research on additive tool design, complex gradient interface research, macro design of gradient interface, and the AFAM-III structural scheme was designed for the friction additive process required for forging performance parts, helping the first university to establish a friction solid phase additive manufacturing research laboratory, and signing a cooperative training agreement for graduate students with a certain university.

- In 2024, due to the increase in the influence of ATIIAM, the Ringgold ID applied for was approved. This year, we also wrote the content of graduate AFAM courses and corporate training lectures, and studied the improvement of the conductivity of copper-aluminum alloys to provide solutions for large machine tool equipment manufacturers.

- In 2025, we published the first English research article in cooperation with partners, updated the website and released the second version of the website, opened the AFRD process to provide free AFAM-I courses, and began to provide technical consultation and AFAMS solutions for friction solid phase additive solutions for enterprises.

- AFAMSology:

- In the long-term research process, we deeply felt that the research on the AFAMS series of solutions went beyond the scope defined by existing disciplines and technologies, and new sub-disciplines may be born in the future. So we learned from Sir Peter Jost (engineer), the father of tribology, and planned to propose the birth of new disciplines to academia and industry with the monograph AFAMSology Friction Additive Technology. We learned from FSW/FSAM researchers, combined Tribology with CNC friction-based AM, and gave a precise definition of AFAMSology: AFAMSology is an emerging sub-discipline that studies the relationship between the mechanism and application of solid-phase friction of metal materials, process optimization and the quality of additive metal materials. It defines the difference from other disciplines and the current popular friction additive methods, and clearly describes several clear directions in the frontier research field of AFAMSology that are most likely to achieve breakthroughs within 3 years.

- AFAMSology represents the direction of the next generation of green additive manufacturing research, advocates compatibility with CNC friction-based and existing material systems, and represents the development trend of future CNC additive and subtractive composite machining centers and additive tools. We look forward to more friends joining the ranks of the first initiators of the emerging discipline!

3. ATIIAM News & Interesting

- Selection of research results AFAMS and its solutions.

- AFAMSology (Friction Additive Technology) is about to be born to the academic and industrial circles. Interested friends are welcome to join the ranks of initiators. AFAMSology is a sub-discipline branch that studies the corresponding relationship between the friction of solid metal materials, the friction process (friction viscosity microstructure metallurgical bonding transformation law) and the quality of additive parts. It is a sub-discipline between tribology and AM manufacturing, which goes beyond the research scope of friction, wear and lubrication defined by traditional tribology. The existing hot melt 3D printing, FSAM with high rigidity and large top forging force, and AFSD special machine tools have similarities, but the core technology concepts are quite different. As the core support system of AFAMSology, AFAMS advocates the integration of multiple contemporary advanced process genes to achieve integrated innovation of core technologies and equipment. The AFAMS program recommends designing a process that matches the target application according to different target applications. For traditional light alloy casting materials, extrusion materials and forging materials, ATIIAM recommends three different structural types AFAMS (I-II-III) for emerging industries, rather than limiting one specific structure/specific process to meet all needs. For example: FSW/FSAM weld nugget refinement, mature deformation strengthening and heat treatment strengthening of light alloys, macro-scale preparation of gradient materials, AI-driven process and parameter optimization, etc. These excellent processes are constantly evolving and will also drive the continuous development of AFAMSology. .

- In order to expand the scope of innovative knowledge dissemination, ATIIAM is looking for strategic partners to establish an AFAMS technology open laboratory. The basic conditions for ATIIAM to select partners are:

- ATIIAM’s first partner company is preferably in the Northwest region of the United States. It is best if you are a representative of a leading company in the industry or a company looking for high-tech achievements to go public.

- The senior management of the partner company should have a broad international vision and a strategic vision to foresee the development hotspots and technological trends of emerging industries in the future.

- The comprehensive strength of the partner should be relatively strong (preferably a medium-sized or larger company), with aerospace, marine, automotive or other professional stable customer sources.

- The partner should have good experimental demonstration conditions (CNC3 equipment programming experience and operators, training venues).

- The partner should preferably have FSW/FSAM and additive manufacturing engineering technology knowledge background.

- Willing to cooperate with ATIIAM online training offline actual operation base, Interested in introducing AFAMS technology in the partner’s products or services

- The partner is willing to support ATIIAM’s original status and AFAMS original solutions,

- The partner has the willingness to start the project and invest funds (the minimum investment should be able to maintain 2 experts working in the Northwest for 1 year, excluding other expenses) or is willing to provide a technology display platform, and jointly look for investors after the financing conditions are mature.

- Cooperation with ATIIAM should not be exclusive (regional non-repetition or application target protection), and should be inclusive of different cultures and customs

4. What services and products does ATIIAM provide? What are the requirements for users who need solutions?

Provide online technical training, professional consulting and technical solutions for AFAMS original technology. Among them, AFAM-I is an open course content that can be read for free (welcome to visit www.atiiam.com, updating now).

For partners who need AFAM-II and AFAM-III courses, we can only provide 1vs1 (manual) customized charging services at present. Please refer to the website for charging standards. Due to the complexity of innovative technologies and solutions, and the limited support capabilities of the company, only customers who have passed AFAM-(I + II) or AFAM-(I + III) training and can maintain good communication can discuss the signing of contracts related to providing solutions.