Our Goal

Make AFAM one of the best additive manufacturing solution for light alloy.

About Us

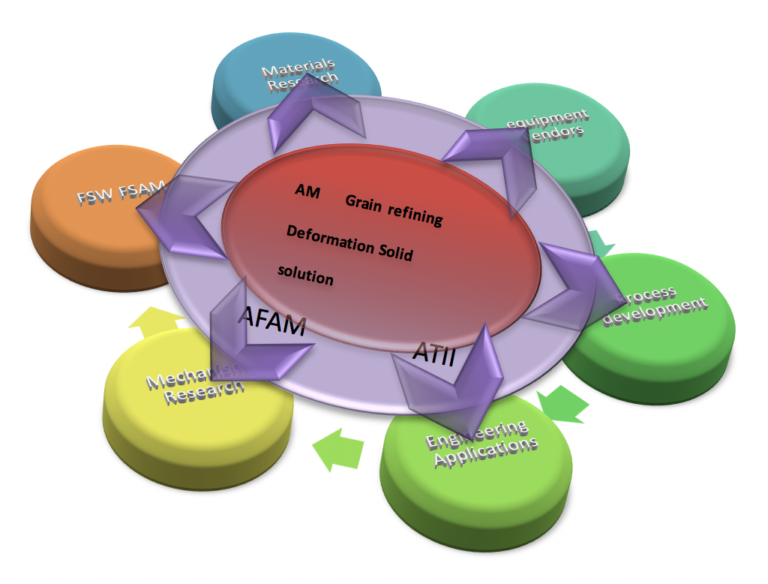

ATII is a premiere tool design, fabrication & consulting company specializing in friction additive manufacturing. It participates and contributes to the solid/semi-solid fraction additive manufacture (S/SSFAM) research and application.

Our core team is consisted of senior integration engineer, big data researcher & automation controlling specialist etc. We formed an alliance to study advanced technology and material science using advanced friction additive manufacture (AFAM) technique patented by ATII in 2015. We have now over sixty members/institutes in the alliance, including material science researchers, universities, hardware and tooling vendor, and industry companies.

We have 30 years of experience with CAD/CAM for system integration and have spent the last three years researching AFAM and using semi-solid formation for additive manufacturing.

There are challenges and opportunities for the friction AM field, challenges come from friction AM tool structure design, continuous material feeding and integration with classic metal strengthening theory; opportunities hide in the process to combine mature machining process with additive manufacturing to produce large scale parts with high mechanical property. From our research we found a way to control material microstructure and achieve additive manufacturing with great mechanical property.

We are ready to share our results with you, and build collaborative relationship.

The ATII AFAM is a platform for you to run mechanism research, material research, device producer, mechanical process developer and applied research.

Our contributions to the international manufacturing industry:

- Under the additive manufacturing concept, brought the disciplines of advanced material science and mature machining process together.

- Solved many challenging problems via tools/method innovation.

- Suggested Complex strengthening mechanism based on grain refine and AFAM system.

- Combined friction & micro-forging solid solution in additive manufacturing, to avoid the defects that come from fusion based process.

- Large scale light alloy part could be made by AFAM in a better, faster, cheaper, easier and more environment friendly way.

- Pioneered AFAM theory, experiment and application.

The genius of the Friction Additive Manufacturing

ATII CTO John tells design legend Wukong Mao’s story of the accidental success of one of the most famous part in the FSW field — the friction additive manufacturing sample. — Reviewed by John

Who would’ve thought that a few specialists would be an innovation company to hold the key to unlock what is then one of the hardest systems in the world now — all started by one guy with an AFAM tool and an idea in a shop.

The history of civilization, in some ways, is a history of additive part: How have we come to build the mechanical world around us in right way? One of the most famous methods is subtractive material part works, but another which unknown in common is friction additive part process, history will be created since its better and cheaper properties.

[Small part. Big idea.]

[John on the ATII]

The FSW invented by TWI in 1991, and came together with AM in 2005, when two different independent ways – welding and AM merged to create a single AM system. It’s difficult such as material clapping and utilization rate.

A new ideal was needed to represent that system so people would know how to ride in right way. Things was in a bad way at initially time. You can see FSW, clapping, feeding, welding factor, mechanism of strengthening, fused and 3D printer etc. — the system were all crammed together at the center of the old ideal, and out in the periphery, there were some that couldn’t even fit on the solution. So the typical solution was vertically accurate like FSW, but maybe not so powerful.

Enter John D. John was a 30-year-old engineering R&D engineer who had been working on and off for the CAD/CAM project. And he had a key insight, and that was that people using additive machine in shops don’t really care what’s happening about its mechanism. They just want to get better and cheaper part from shop in efficiency manner –”How do I go on? How do I run in easer and right way?”

It’s the system that’s important, not the mothed. He’s taken this complicated mess of spaghetti, and he’s simplified it. He found the root factor to mess – stir is redundancy in AM, it was demonstrated by his later test. Likewise, at AFAM initial level he inserted the AM into typical manufacturing smartly, he’s made everything correspond to the subtractive process, so worker could know immediately and he’s fixed it, first AFAM part to be accomplished.

- In 2018, someone company decided, at last, to give John’s method a try. They did a test ran on common condition of these new ideal, and were gone in one day. They realized they were onto something, they printed some more samples of part, and this is the samples that you will be printing tomorrow.

John’s design could be really became the template for the way we think of light alloy AM industry maps today, since its better, cheaper and easier way — all of them convert complex questions into additive crisp geometry. All of them use typical mechanism in usual to merged in one additive intension process, such as grain refine, deformation and solid solution etc. They are all part of a new additive universal language seemingly in next decade. - John wouldn’t have known what is a complex strengthening mechanism of light alloy was, but that’s really what he designed and he really took that challenge and broke it down to three principles:

First one is focus. Focus on who you’re doing this for. He has made lots of experience on how to add and feed. - The second principle is simplicity. What’s the shortest way to deliver that need? He abstracted AM necessary and sufficient conditions are squeezing and friction from mess clearly.

Finally, the last thing is: Thinking in a cross-disciplinary way. He has introduced a composite strengthening mechanism could be used in efficiency for friction additive manufacturing, which include friction solid solution!